Water, Wastewater and Wineries and DAQFactory

Summary:

- Old system required driving 150-200 miles per day per operator

- New system: DAQFactory remote monitoring of all sites, no driving necessary!

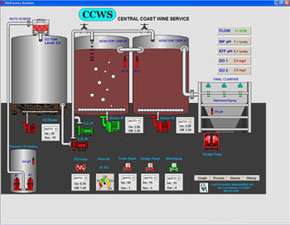

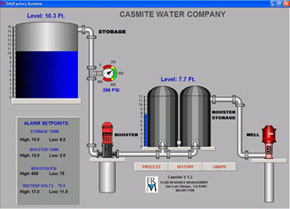

- Realtime display, alarming, remote setpoint control of each site

- Saved tens of thousands of driving miles a month plus operator time

Fluid Resource Management provides design/build/operation services to the Water, Wastewater, and Winery industries throughout California. Part of our service to our clients is providing cost effective operation support to various sites, some of which are in remote areas of our service area. Our typical operator could easily drive 150-200 miles per day making the "rounds" to his assigned clients with alot of unproductive windshield time.

FRM saw the potential of using DAQFactory coupled with RFSCADA products and the Internet to provide remote monitoring of alarm conditions and provide a reliable method for remote setpoint control. This, coupled with the graphing and logging capability allows FRM to troubleshoot each system in realtime from our office and in many cases correct the situation with just a phone call to the client's staff. In other cases, using the alarming feature built into DAQFactory, we can respond and affect repairs quickly by knowing ahead of time what exactly the problem is.

Since using DAQFactory, our staff has become more productive by not being required to make daily visits to check tank levels, residuals, pH/D.O. levels, and log pump runtimes. The annual cost savings to our company in fuel alone is remarkable. One particular client required daily site inspections to record a number of data sets. At 100 miles roundtrip, it was clear that remote site monitoring/control would be effective in holding the cost down to our client.

Using DAQFactory and RFSCADA equipment, the site is now fully automated and process alarmed. This allows FRM staff to monitor the system from our office, and has cut back the number of trips from seven per week to once per week. A savings of over $500 per month in fuel alone. The drive time normally spent everyday is now used for other projects that actually benefit from having onsite personnel.

-Chuck Ellison, Fluid Resource Management